NITHA Aerospace Private Limited

Built for Aerospace, Defence

Energy & Precision Engineering

Advanced Materials Expertise · Product & Process Excellence · Indo-European Advanced Solutions

VIEW MORE PRODUCTS

At NAPL, we don't just manufacture fasteners — we engineer confidence in every connection. Specializing in super alloy fasteners for aerospace, oil & gas, energy, and space systems, we design and produce components that meet the world's most demanding engineering standards.

Our solutions are built for environments where failure isn't an option — from high-vibration jet engines to corrosive deep-sea rigs and thermal extremes in space. Whether it's a bolt, nut, stud, or custom component, every fastener is purpose-built for performance.

Our advanced Industries 4.0-enabled manufacturing facility integrates smart processes, real-time quality monitoring, and precision machining. Every product is crafted to meet tight tolerances, exacting thread profiles (MJ, UNJF, etc.), and stringent material specifications.

We work with some of the world's most trusted high-performance materials — Titanium, Inconel, A286, Monel, and more. These superalloys offer unmatched strength, corrosion resistance, and thermal stability — qualities essential for critical industries.

From design, casting, and forging to CNC machining, heat treatment, surface finishing, and final inspection — we control the entire manufacturing lifecycle in-house. This allows us to guarantee both performance and traceability.

As a metallurgy-driven startup, we proudly contribute to India's strategic manufacturing ecosystem. Our mission is to indigenize high-precision fastening solutions that match global aerospace standards.

At NITHA Aerospace, casting is the foundation of strength. We produce ingots through controlled casting processes using ferrous, non-ferrous, and superalloy materials. Our casting capabilities are tailored for critical industries such as aerospace, oil & gas, where dimensional consistency and internal soundness are essential. With a focus on net-shape accuracy and material purity, our casting process ensures optimal grain structure and reduces downstream machining.

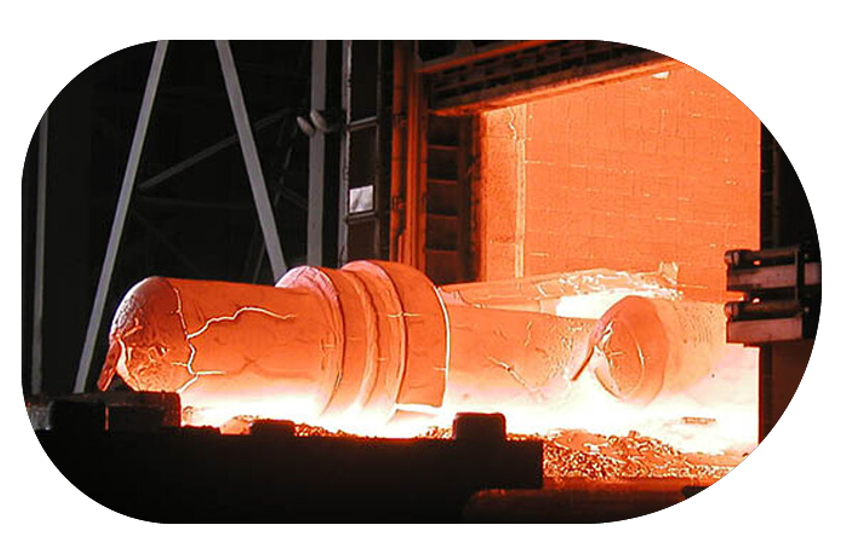

Strength Forged Under Pressure.

We utilize closed-die forging to shape fasteners with superior grain orientation and mechanical strength. This process is ideal for components that operate under high load, temperature, or vibration — such as aerospace bolts, studs, and structural connectors. Forging enhances fatigue resistance, impact tolerance, and material efficiency. At NITHA Aerospace, we forge with Titanium, Inconel, and other high-performance alloys, ensuring that every fastener is as strong as the mission it supports.

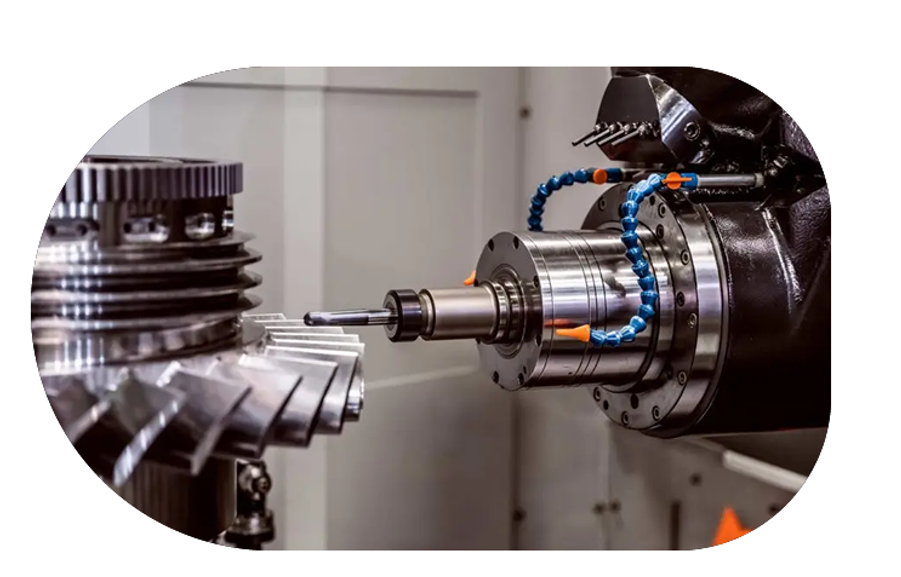

Where Tolerance Meets Perfection.

Our in-house CNC machining and multi-axis turning centers allow us to produce fasteners with extremely tight tolerances and complex geometries — including MJ, UNJF, UNR threads and more. We specialize in machining superalloys and exotic materials, meeting aerospace and standards for thread integrity, surface finish, and dimensional precision.

Each part is digitally validated through real-time inspection systems — because in critical applications, perfection is the only tolerance we accept.

Performance You Can Feel — Engineered at the Molecular Level.

Through controlled heat treatment processes, we enhance the hardness, tensile strength, and fatigue resistance of our fasteners. Whether it's solution annealing, age hardening, or stress relieving, our thermal treatment cycles are tailored to each alloy and application.

Engineered Finishes. Real-World Endurance.

Our surface treatment division protects fasteners against corrosion, wear, and environmental stress. We offer passivation, plating, anodizing, and protective coatings compliant with aerospace and military specifications.

From space-bound satellites to deep-sea rigs, our surface engineering ensures fasteners remain reliable in the harshest conditions — with perfect adherence, surface uniformity, and coating thickness.

Every Fastener Proven. Every Performance Measured.

Innovation begins in the lab. Our R&D and testing facility supports design optimization, material validation, and quality control through:

Our commitment to testing ensures every fastener not only meets — but exceeds — its intended purpose.

One Platform For All Your Fasteners Requirements

Single window for end-to-end steel sourcing

Explore Nowwww.nithaaerospace.in © Copyright and Private Limited. All Rights Reserved | Terms of Access